LR.pdf/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

TZ D chillers with integrated free cooling configuration

2 product versions

- Standard chiller

- Free cooling chiller

3 refrigerants available

- R-1234ze (EWA/FH)

- R- 513A (EWA/FS)

- R-134a (EWA/FD)

4 efficiency tiers

- Blue (B-)

- Silver (S-)

- Gold (X-)

- Platinum (P-)

Capacity range

Operating range

Product overview

Product Benefits

1. Daikin Single-Screw Compressor design

The Daikin single screw compressor design. This type of technology is designed to be extremely reliable, even in harsh environments. Because the main rotor is balanced in both radial and axial directions, the compressor bearing achieves exceptionally high reliability.

2. Outstanding reliability ensured by Daikin’s in-house Inverter

Two separate and independent refrigerant circuits ensuring maximum safety and ease of maintenance.

3. Cutting-edge efficiency thanks to Daikin’s in-house VFD & Variable Volume Ratio

Daikin VFD allows the unit to operate optimally, reducing and controlling running costs in every working condition. The in-house single-screw compressor is integrated with the Variable Volume Ratio (VVR), which modulates the compression ratio enhancing the efficiency of the compressor with varying ambient conditions.

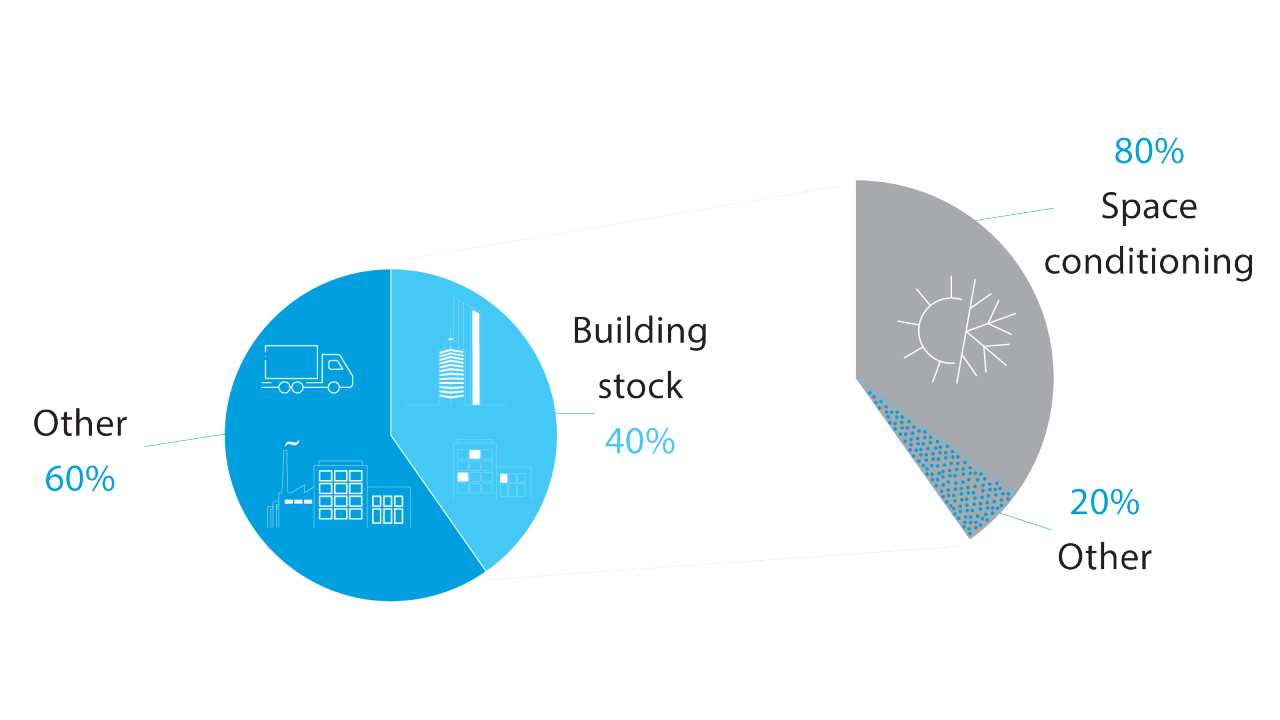

AIR CONDITIONING: A NECESSITY THAT AFFECTS RUNNING COSTS

DAIKIN: A WISE CHOICE TO REDUCE RUNNING COSTS

4. Integrated Active Harmonic Filter by Daikin

Active harmonic filters (AHFs) reduce harmonic distortion in electrical systems and compensate for harmonic currents in real time, improving the system’s power quality. The active harmonic filter by Daikin is fully integrated into the chiller.

Fully integrated means:

- no additional space required

- no additional installation activity

- full assembly is factory tested

- does not require additional maintenance

5. Daikin TZ D units are extremely compact

Despite the free-cooling mode, Daikin TZ D units are extremely compact. This is due to a special redesign of the condenser section, which not only reduces the space required but also improves the overall efficiency of the system.

6. Free cooling configuration does not require any additional space

They do not take up any extra space compared to a standard chiller without free cooling capability.

Options integration

7. Wide operating envelope

The TZ D units can operate in a wide range of conditions, making them suitable for a variety of applications. They can provide chilled water for applications such as ice rinks with temperatures as low as -15°C, while also being suitable for data centers that require higher evaporator outlet temperatures of up to 30°C. This versatility provides exceptional flexibility, allowing TZ D units to operate effectively in a wide range of environments and climates

Operating envelope

Heat recovery to optimize energy use

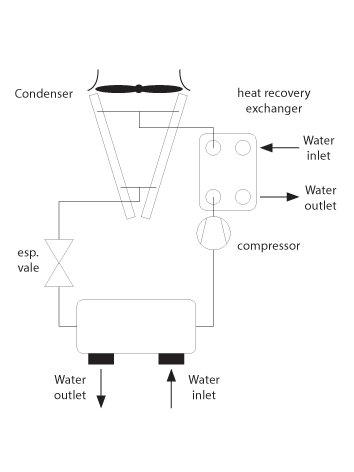

8. The possibility of integrating the Total or Partial Heat Recovery options

This allows the recovery of some or all the heat produced during the cooling process. This improves energy efficiency and reduces operating costs. With Total Heat Recovery, the unit is equipped with an additional condenser per circuit to produce hot water. With Partial Heat Recovery, the unit is equipped with one desuperheater per circuit to produce hot water. This heat recovery system allows the production of hot water that can be used for specific applications needs.

When heat recovery is ON, the unit efficiency to consider is not the EER ( Energy Efficiency Ratio) which refers only to the cooling effect of the unit. With heat recovery the unit also providing heating energy that otherwise should still be provided by another source. The Total Efficiency Ratio is defined as:

TER = Cooling capacity + Heating capacity

─────────────────────

Power input

A useful integration for various applications

9 . Performance monitoring option available

The unit’s performance information is available directly from its controller, which provides real-time data as well as the historical performance of the unit. This allows to monitor the unit efficiency and make the necessary adjustments to maintain optimum performance. By tracking performance data, it is possible to identify anomalies or deviations early on, allowing to detect and manage potential problems before they lead to failures.

10. These units can be integrated into a complex system comprising several Daikin units

Effective management of this group of units is essential to optimise operating hours and ensure proper functioning. This can be achieved with the Intelligent Chiller Manager (iCM) option, which optimises systems of up to 8 units, and the cloud remote monitoring tool Daikin on Site. Daikin iCM can be connected to Daikin on Site, a cloud-based monitoring platform that interfaces with building management systems (BMS).

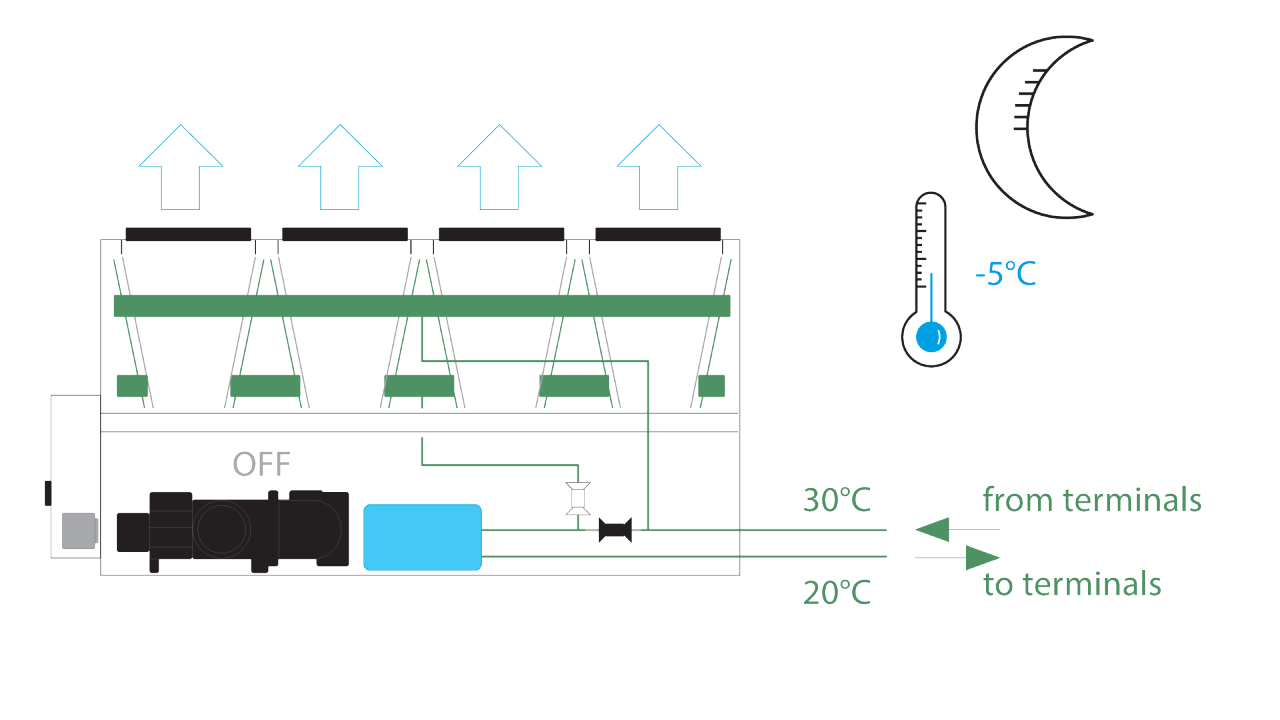

Free cooling configuration

Open Loop (with glycol)

Free cooling system is designed to chill the fluid by esploiting cold energy from the environment. When outdoor ambient is above fluid temperature the unit provides the cooling capacity using only the compressors (Mechanical cooling mode). When the ambient temperature drops below the temperature of the fluid entering the unit, outdoor air can be used to chill the fluid before it reaches the evaporator, moving from partial to Full free cooling according to ambient temperature variation.

Closed Loop (without glycol)

The unit’s brazed plate heat exchanger create a closed loop with the free cooling exchanger and a dedicated pump. In this system the glycol is confined in the closed loop. The glycol free option operates with a “closed loop” system, providing a compliant and efficient solution for applications where avoiding the use of glycol is preferred. Among its benefits, it can lead to significant cost savings as the avoidance of glycol in the customer’s system makes it easier to maintain and improve overall efficiency. In industrial processes, it reduces the risk of contamination, ensuring that product quality is not compromised.

The 3 key benefits of glycol-free configurations

Learn more

-

%20LR.pdf/_jcr_content/renditions/cq5dam.thumbnail.319.319.png) EWA_FD_H_S-TZ D brochure (ECPEN24-404) LRPDF | 851.22KB

EWA_FD_H_S-TZ D brochure (ECPEN24-404) LRPDF | 851.22KB